The process is different from electric discharge electron beam laser and plasma arc machining in that the process does not depend on heating of the workpiece to the point of evaporation.

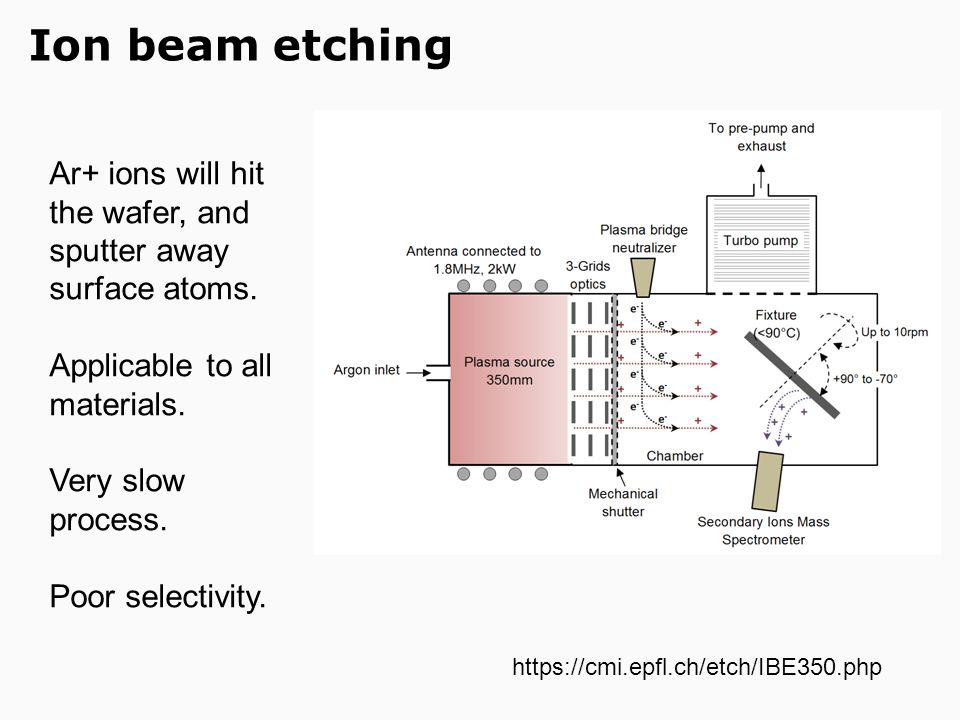

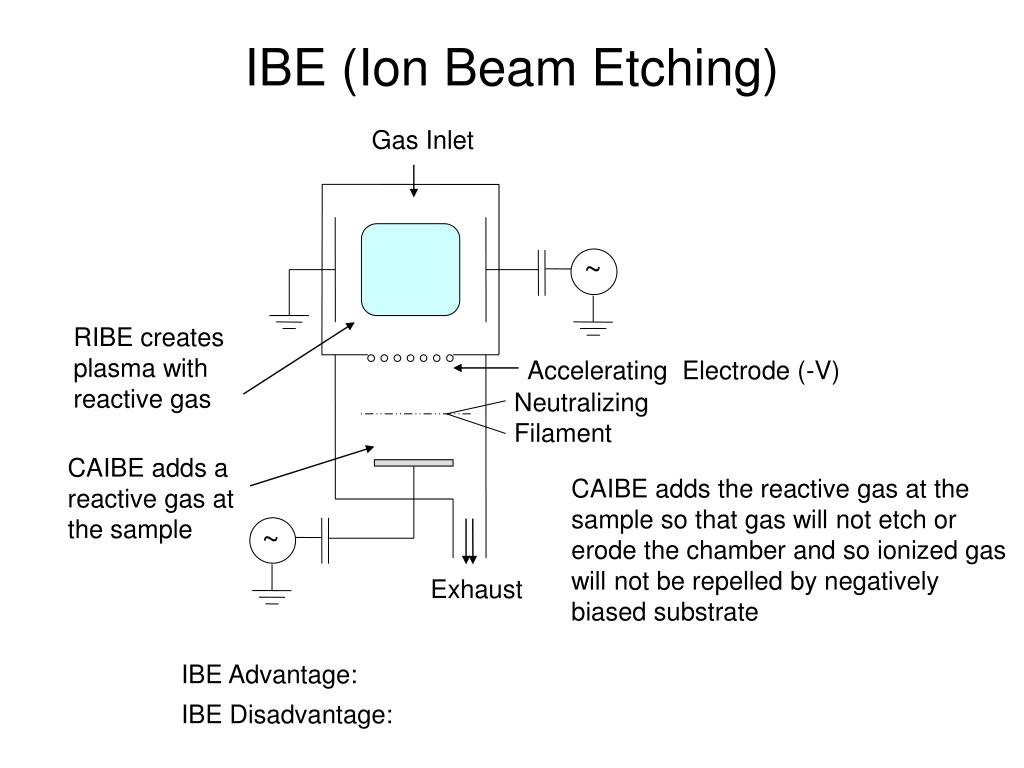

Ion beam etching process.

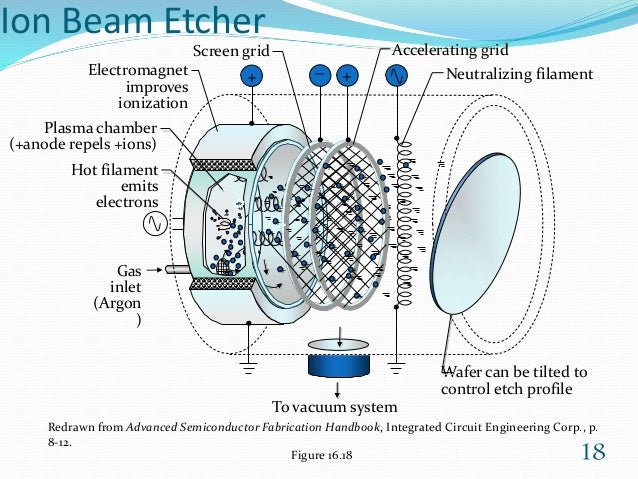

The three main parts of the ion beam source are the discharge chamber the grids and the neutraliser.

Rie uses chemically reactive plasma to remove material deposited on wafers.

It enables highly directional beams of neutral ions to control over the sidewall profile as well as radial uniformity optimisation and feature shaping during nanopatterning.

In essence an ion beam source is a plasma source having a set of grids that enable extraction of a stream of ions.

The ion beam etching ibe is a physical dry etch process.

Ion production is done in the discharge chamber by subjecting a gas like argon to an rf field.

The plasma is generated under low pressure vacuum by an electromagnetic field.

Ion beam etching or milling is achieved by directing a beam of charged particles ions at a substrate with a suitably patterned mask in a high vacuum chamber.

Plasma and ion beam etching deposition technology.

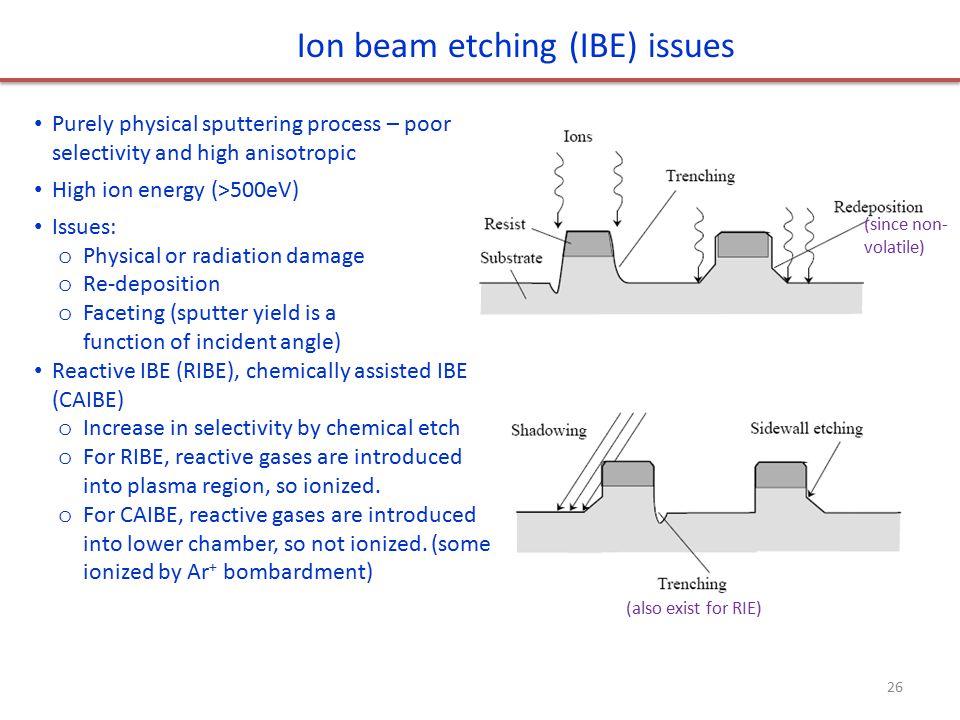

This can lead to increased etching rate or higher material selectivity of the etching process.

Oxford instruments plasma technology is a world leader in plasma process solutions with a long history of providing the latest technology innovations in plasma processing.

A fib setup is a scientific instrument that resembles a scanning electron microscope sem.

Ion beam etching also known as ion beam milling or ion milling is the most widely used etching method for preparing solid state samples for scanning electron microscopy sem applications.

Ibm or etching is generally a surface finishing process in which the material removal takes place by sputtering of ions.

Reactive ion etching rie is an etching technology used in microfabrication.

Focused ion beam also known as fib is a technique used particularly in the semiconductor industry materials science and increasingly in the biological field for site specific analysis deposition and ablation of materials.

Because of the energy of the ions they strike out material of the surface.

The electric short fail trend of the perpendicular magnetic tunnel junctions p mtjs caused by the ion beam etching ibe process is studied at various ion beam angles and cell to cell space widths.

The number of electric short fails increases markedly at an ion beam angle greater than 35.

The chemically assisted ion beam etching uses the technology of ion beam milling or ion beam trimming and adds additional reactive gases close to the substrate typically by a gas ring.

In this process the sample material is bombarded with high energy argon ion beams in a high vacuum chamber.

.jpg)